- What is Panel Processing? The Starting Point

- Core Components of Automated Panel Processing machine

- Automation vs. Traditional for Panel Processing

- Embracing Automation: Advantages and Cons

- Panel Processing Pain Points

- Risks and Professional Responses to Customizing Auto Panel Processing Machines

- How to Choose the Right Panel Processing Machine for You

- Industry Trends: Where is the Future of Panel Processing?

- FAQ

- Conclusion

In today's furniture manufacturing industry, if you're still talking about "craftsmanship," you might be missing out on an era. A true revolution has taken place—from dusty, handcrafted workshops to brightly lit, intelligent factories. At the heart of this revolution is Panel Processing.

Welcome to Caelus's industry analysis. Today, we won't discuss abstract concepts, but rather focus on the Auto Panel Processing Machine that is reshaping the woodworking industry.

This is not just about efficiency and precision, but also about how your business can achieve woodworking automation and ultimately realize profitability in a fiercely competitive market.

What is Panel Processing? The Starting Point

Panel Processing is the cornerstone of modern panel furniture manufacturing.

Imagine your wardrobe, cabinet, or desk. They are all assembled from standard panels (such as MDF, particleboard, and plywood) through a series of precise processes.

This process of "breaking down the whole into parts and then reassembling them" is Panel Processing. It mainly comprises three core processes:

Cutting: Precisely cutting large boards into the required component sizes.

Edging: Sealing the edges of the cut boards to enhance aesthetics, provide moisture protection, and safeguard the boards.

Drilling: Drilling connection holes and hardware holes in the boards according to the design drawings.

In the past, these processes heavily relied on manual labor. However, the advent of woodworking CNC machines has automated this entire process.

Core Components of Automated Panel Processing machine

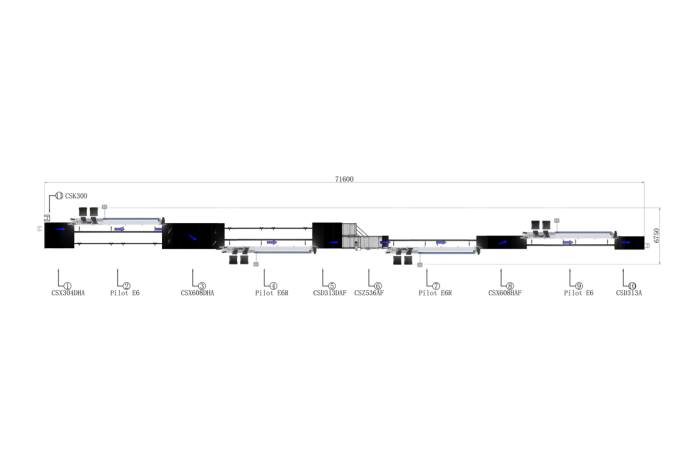

An Auto Panel Processing Machine is not a single device, but a collaborative intelligent system. It's like a highly coordinated "robot orchestra," with each part performing its specific function and playing a precise symphony.

As professional woodworking machine manufacturers, our automated systems should include the following machinery:

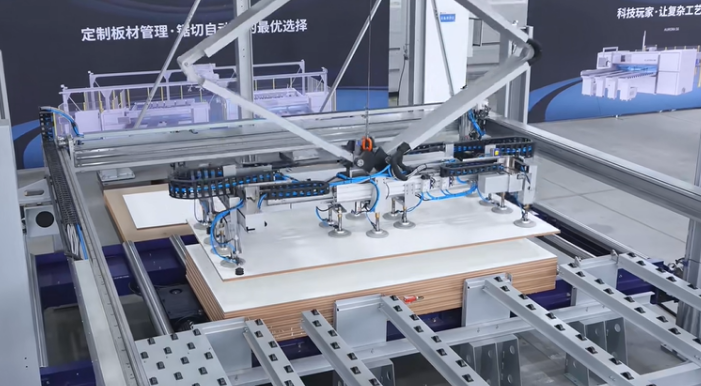

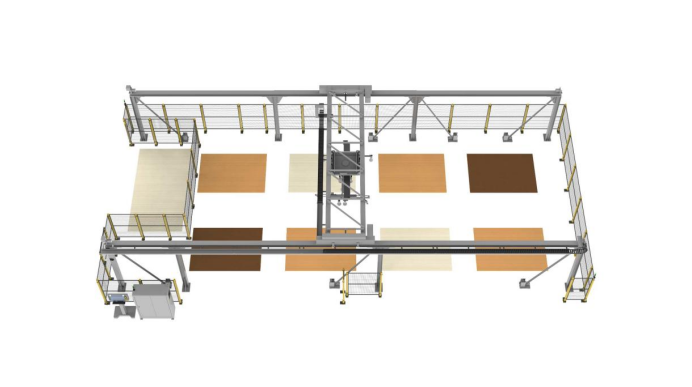

- Panel Storage System

Core Positioning: The "Central Scheduling Brain" and "High-Efficiency Logistics Center" for Automated Production

Traditional sheet metal storage relies on manual labor, forklifts, and flat stacking, leading to three major pain points: wasted space, inefficient searching, and sheet metal damage.

Caelus' StoreTek 5 intelligent storage system completely revolutionizes this model. It's not just a "warehouse," but a smart logistics hub that interfaces in real-time with your entire production management system.

Working Principle: The system uses high-rise racking for three-dimensional storage, increasing space utilization several times over. When a production order is placed, the software system immediately locates the required sheet metal. High-speed, precision robotic arms (stall cranes or gantry cranes) automatically and safely grab the "correct" sheet metal and deliver it "on time" to the next workstation (Panel Saw) via an optimized path.

Core Value:

Automation and Safety: It achieves full automation from warehousing and management to outbound delivery, representing a solid first step towards "unmanned production" and completely eliminating the safety hazards of forklifts and manual handling.

From Sheet Metal to Machine: The Smart Storage System seamlessly integrates data and material flow. It ensures the Panel Saw always has enough panels, eliminating production line downtime caused by manual material searching or incorrect material selection.

Real-time Inventory Management: The system digitally manages each sheet of panel, providing a clear overview of inventory levels and achieving zero errors and ensuring FIFO (First-In, First-Out) compliance.

- Panel Saw

Core Positioning: A High-Precision, High-Efficiency "Value-Added Cutting Hand"

In sheet metal processing, cutting is the first step in cost savings. Cutting precision determines the quality of subsequent Eage Banding, while cutting efficiency determines the overall workshop capacity.

Caelus's high-end Panel Saw is a "cutting hand" designed for high-volume, high-intensity production.

Working Principle: It's more than just a "saw." The core lies in its intelligent optimization software. This software calculates the optimal cutting plan within seconds based on the order (like "Super Tetris"), maximizing panel utilization. A servo motor-driven high-speed saw and an electronically controlled feeding robot ensure extremely high speed and stability in the cutting process.

Core Values:

Maximum Material Utilization:** The intelligent layout software is a true "money-saving tool." Compared to manual layout, it can increase material utilization by 5%-10%, meaning significant annual savings in raw material costs.

High Precision and Zero Chipping: The Caelus high-end model features a heavy-duty body and precision guide rails, ensuring cutting accuracy within ±0.1mm. Combined with its large and small saw blade design, it achieves a clean, chip-free cut, a prerequisite for perfect edge sealing.

Seamless Integration: It can seamlessly connect with the StoreTek 5 intelligent hopper, enabling automatic feeding, cutting, and unloading, forming a highly efficient "warehousing-cutting" work unit.

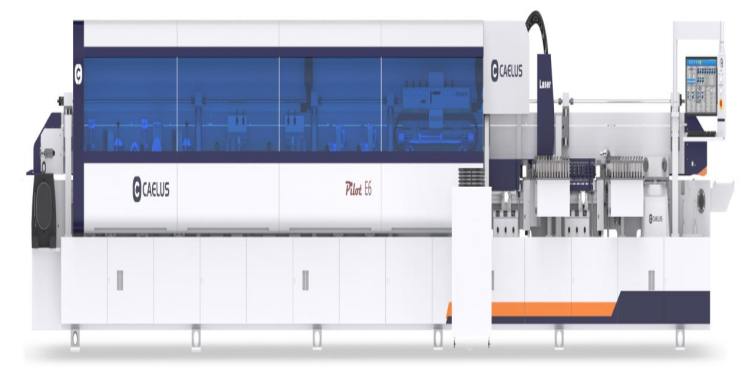

- High-Speed Automatic Eage Banding Machine

High-Speed Automatic Eage Banding Machine

Core Positioning: The "Aesthetic Refiner" Determining Furniture's Grade and Lifespan

Edge banding is the "face" of panel furniture and also the most demanding stage of craftsmanship. A rough, overly glued, or peeling Eage Banding can ruin a high-end cabinet.

Caelus' Eage Banding machine is the "refiner" pursuing ultimate quality.

Working Principle: Automatic Eage Banding is a continuous operation involving more than ten processes, including pre-milling, glue application, Eage Banding, pressing, end trimming, rough finishing, fine finishing, chamfering, scraping, and polishing. The "high-speed servo control" of the Aurora E8x series is key.

Core Values:

Visual Aesthetics of "Zero Glue Lines": With a precise glue application control unit and a powerful pressing system, supporting PUR glue for enhanced waterproofing and heat resistance, when using PUR adhesive the Caelus Eage Banding machine achieves a near-invisible "zero glue line" effect, significantly elevating the quality of furniture.

Flexible Production with Servo Control: "High-speed servo control" means that all machine work units (such as finishing and chamfering) can automatically switch. When the production line needs to switch between different thicknesses of boards or Eage Banding tape, the operator does not need to stop the machine for manual adjustment; the machine can automatically adjust with a single button. This is crucial for small-batch, multi-variety customized furniture production.

Perfect Detail Finishing: With features such as a high-frequency motor and four-motor tracking chamfering (corner rounding), it ensures that the banded edges are rounded, smooth, and non-sharp, achieving a leap from industrial products to works of art.

- CNC Machining Center (Woodworking CNC Machine)

Core Positioning: A "Super All-Rounder" Achieving Customization and Efficiency

After the sheet metal is cut and edge-banded, it needs to be drilled with holes for connecting and installing hardware. Traditional methods (such as multi-drill sets) require manual repeated flipping and positioning, resulting in low efficiency and a high error rate.

Caelus' CNC 6 Sided Drilling Machine completely solves this bottleneck of repeated flipping and positioning.

Working Principle: An "all-around" woodworking CNC machine with intelligent dual drill bits and a multi-column tool magazine to meet various process requirements.

Smarter Value:"One-time positioning, six-sided machining": This is the revolutionary advantage of the Caelus CNC 6 Sided Drilling Machine. The sheet metal only needs to be fed in once, and the machine's upper and lower drilling groups and side drilling groups work simultaneously. Before the sheet metal is released, all holes (vertical holes, horizontal holes) and grooving processes on its six sides are completed.

Exponential Efficiency Improvement: Adopting a forward-to-back (FRO) mode, the next panel can be processed immediately after the previous one is completed. The entire process is smooth with short downtime. This FRO mode can be integrated into production lines, achieving the level of a dual-station PTP drilling machining center.

Zero Errors and High Precision: Since manual panel flipping and secondary positioning are eliminated, problems such as hole misalignment and assembly difficulties caused by human error are fundamentally prevented, ensuring high-quality final products. In automated production lines, it is a key efficiency node connecting Eage Banding machines and packaging machines.

Automation vs. Traditional for Panel Processing

Why is woodworking automation an irreversible trend? A comparison table speaks volumes.

Table 1: Automation vs. Traditional Woodworking

|

Dimension |

Auto Panel Processing Line |

Traditional Methods |

|

Efficiency |

High-speed, 24/7 capability |

Manual-dependent, slower |

|

Precision |

CNC controlled (e.g., ±0.1mm) |

High risk of human error |

|

Labor Cost |

Reduced labor, high initial cost |

High long-term labor cost |

|

Data & Mgmt |

Real-time tracking, visualized |

Difficult to track, reliant on paper |

|

Safety |

High, enclosed processes |

Higher risk of accidents |

|

Scalability |

Easy to scale production |

Difficult to scale quickly |

The conclusion is clear: automated production lines offer overwhelming advantages in efficiency, precision, and long-term cost control.

Embracing Automation: Advantages and Cons

Introducing an Auto Panel Processing machine is undoubtedly a wise move, but Caelus insists on providing customers with a comprehensive overview:

Advantages (Pros):

Ultimate Efficiency: Inline production eliminates the need for manual intervention, enabling 24/7 (anytime, anywhere) operation.

Stable Quality: Eliminating reliance on manual labor, CNC control ensures that the cutting and edge-sealing precision of each panel meets international standards.

Data-Driven: Visualized production data, easily integrated with MES(Manufacturing Execution System)/ERP(Enterprise Resource Planning) systems for intelligent management.

Controllable Costs: Significantly reduces labor costs and panel waste.

Potential Challenges (Cons):

- Initial Investment: The initial investment for a high-quality automated production line is relatively high.

- Technical Requirements: Requires a professional operator and maintenance team (Caelus provides comprehensive training).

- Planning Requirements: Requires careful planning of the factory layout.

Panel Processing Pain Points

As an experienced manufacturer of automated woodworking machines, we understand the pain points of traditional factories. Our automated panel processing solutions were created to solve these problems.

Table 2: Panel Processing Pain Points & Caelus Solutions

|

Common Pain Point |

Root Cause |

Caelus Solution |

|

Panel Waste |

Inefficient manual layout |

Smart nesting software (Auto Nesting) |

|

Poor Edge Quality |

Unstable glue/temp control |

Aurora Series high-speed Eage Banding |

|

System Incompatibility |

Multiple vendors, no integration |

Caelus full-line integration solution |

|

High Labor Cost |

Manual handling between steps |

Smart Storage & automation |

|

Delivery Delays |

Low production efficiency |

High-speed cutting & drilling line |

Risks and Professional Responses to Customizing Auto Panel Processing Machines

Auto Panel Processing Machines Line

Customizing an Auto Panel Processing Machine is a complex and challenging system engineering project. Professional manufacturers can leverage their expertise, technology, and streamlined management processes to integrate risk identification and mitigation into every stage of the project.

- Core Risks of Customizing an Auto Panel Processing Machine

The risks of a customization project primarily focus on three phases:

Planning and Requirements Risks: Discrepancies may arise between the manufacturer and the customer regarding the definition of functions and parameters. Key risks include: requirements creep over during the project; and insufficient environmental adaptability, such as incompatibility between machine size or logistics routes and the customer's factory layout. Furthermore, excessive pursuit of functional compatibility may lead to a degradation of core machine performance.

Technology Integration Risks: The machine must seamlessly integrate with the customer's existing IT infrastructure and third-party hardware. Key risks include: insufficient software interface compatibility, leading to communication barriers between the MES/ERP system and the machine's PLC, resulting in "data silos"; and hardware incompatibility or cycle time conflicts when integrating multi-brand machine.

Machine Operation and Lifecycle Risks: The risk after delivery of an Auto Panel Processing Machine lies in its ability to continue operating. The main challenges are the difficulty in procuring non-standard spare parts, leading to prolonged downtime when critical customized components fail; and the lack of operator understanding of customized functions, affecting operational reliability.

- The Response and Resolution Process of a Professional Auto Panel Processing

Machine Manufacturer Professional manufacturers integrate risk management into standardized processes to ensure the smooth implementation and long-term stable operation of customized projects:

Strict Requirements Lock-in and Design: By signing technical specifications, all technical parameters are locked in before project initiation to prevent requirement creep. Simultaneously, 3D layout analysis and modular design principles are used to ensure that the machine adapts to the customer's environment while maximizing the use of standardized components to guarantee basic performance.

System Integration and Quality Control: As the leading system integrator, the manufacturer manages all hardware and software interfaces to ensure efficient collaboration between devices. The most critical quality assurance step is performing FAT (Factory Acceptance Testing), which uses the customer's real data and materials to verify the reliability of customized functions before delivery. This effectively transfers integration risks to the manufacturer's control.

Comprehensive Post-Delivery Support: To address operational risks, the manufacturer provides a list of non-standard spare parts and strongly recommends that customers stockpile them in advance. Simultaneously, to ensure operational reliability, specialized technical documentation and training must be prepared for customized functions, enabling on-site personnel to fully master the unique capabilities of the machine.

Successful implementation of customized projects requires strong engineering capabilities and a high degree of responsibility from the Auto Panel Processing production line manufacturer. Caelus's strength lies in our ability to apply stringent international quality standards to a flexible customization process. Leveraging a robust supply chain and leading R&D background, we are committed to modular design and system integration, ensuring that while meeting unique customer needs, we minimize the risk of problems arising on the Auto Panel Processing production line. We help customers avoid customization pitfalls and achieve “Smart Tech · Smarter Value”.

How to Choose the Right Panel Processing Machine for You

Right Panel Processing Machine

When purchasing machine, don't just look at price and brand. Caelus suggests considering the following six key factors:

- Automation Level: Do you need single-machine automation (e.g., one Panel Saw) or full-line automation?

- Sheet Material Type: What are the main sizes, thicknesses, and materials of the sheets you process?

- Factory Layout: Are your workshop space, power supply, and dust removal systems compatible?

- Brand and Standards: Does the supplier have international certifications (e.g., CE certification)? This is crucial for the safety and durability of the machine.

- Integration Capability: Can the supplier provide complete line integration solutions, or just "piece together" machine? Caelus has strong capabilities in complete line integration and software interoperability.

- After-Sales Service: Can multinational woodworking machine manufacturers provide timely localized service and training?

Caelus offer more than just machines; we provide high-performance, cost-effective whole-plant solutions based on international standards (supported by the KDT Group supply chain) and intelligent technologies (Australian R&D background). Our machines are manufactured strictly according to CE safety standards, and our R&D team comprises experts with numerous patents in various cutting-edge fields.

Industry Trends: Where is the Future of Panel Processing?

The future of panel processing is moving towards automated woodworking manufacturing.

AI + IoT: machine is no longer an island. The Internet of Things (IoT) connects all machines, and AI optimizes production processes and even predicts when machine needs maintenance.

Flexible Manufacturing: Facing the growing demand for personalized customization, automated production lines must be able to quickly switch orders and handle small-batch production.

Green Manufacturing: Future woodworking CNC machines will focus more on energy conservation and dust control, achieving environmentally friendly production.

FAQ

Q1: What is an Auto Panel Processing machine?

A: It's not a single machine, but a smart production system integrating intelligent warehousing, automatic Panel Sawing, automatic Eage Banding, and automatic CNC drilling for efficient production of panel furniture.

Q2: Which companies are best suited to implement automation?

A: Any panel furniture company seeking to improve production efficiency, ensure product quality, reduce labor costs, and achieve large-scale production should consider automation.

Q3: Can the automation system interface with my design software?

A: Yes. Caelus' automation system seamlessly integrates with mainstream CAD/CAM design software, enabling direct data flow from design to production.

Q4: What technical support does Caelus provide?

A: Caelus provides full lifecycle services, from factory planning, machine selection, installation and commissioning, operation training to global after-sales maintenance.

Conclusion

Automated panel processing machines are no longer a future concept; they are an essential tool for furniture manufacturers to transform their businesses.

From manual operations to automated panel processing, the change isn't just about speed and precision, but also about a company's core competitiveness. Caelus Intelligent machine, with its international perspective, robust supply chain, and intelligent technology, is committed to providing global customers with cost-effective woodworking automation solutions.

Don't just "watch" the panel process revolution; it's time to "join" it.

Want to learn how to upgrade your factory to a smart and automated woodworking factory?

Contact the Caelus Intelligent panel processing machine expert team now for a free one-on-one consultation and complete line planning.