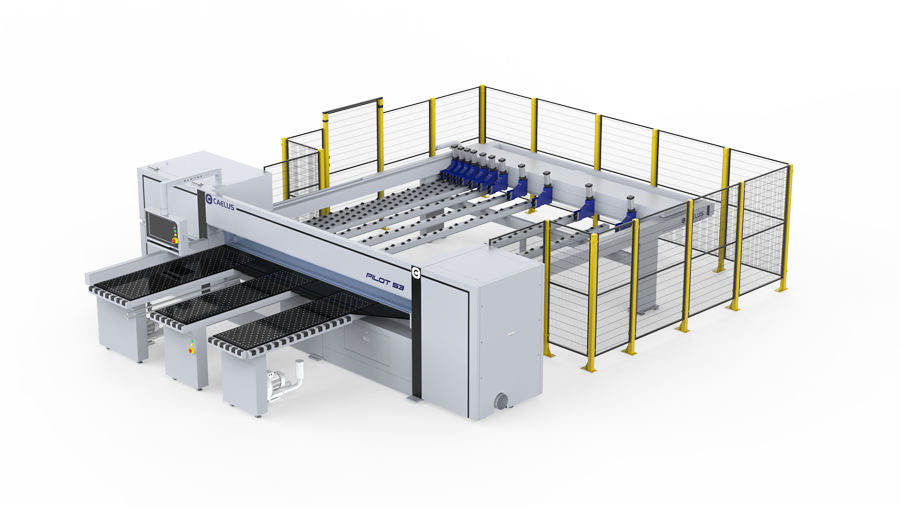

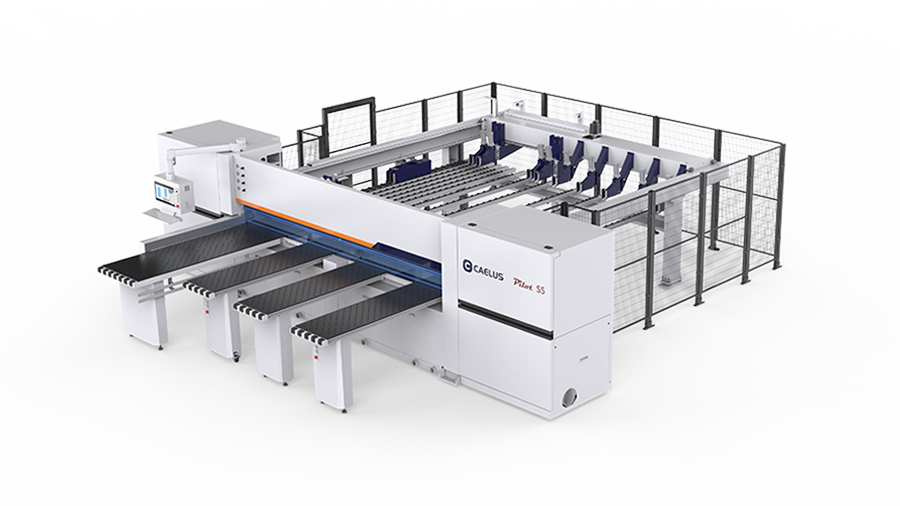

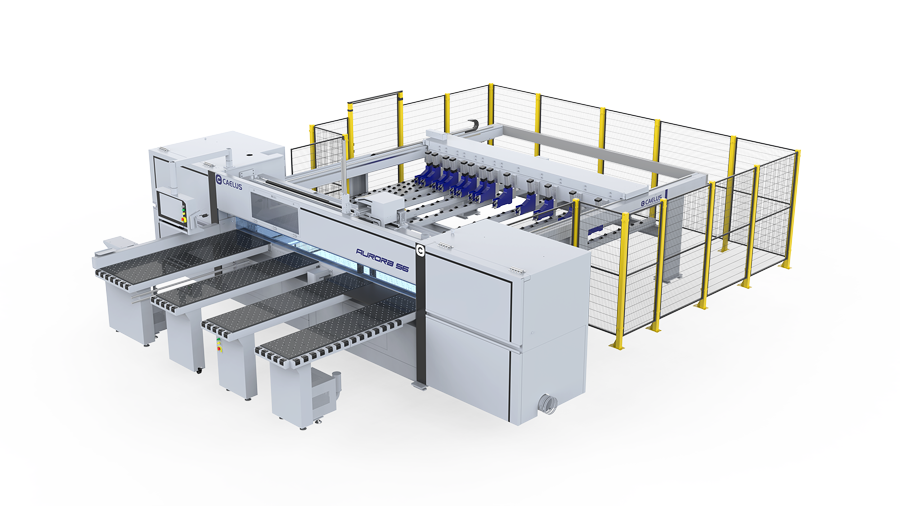

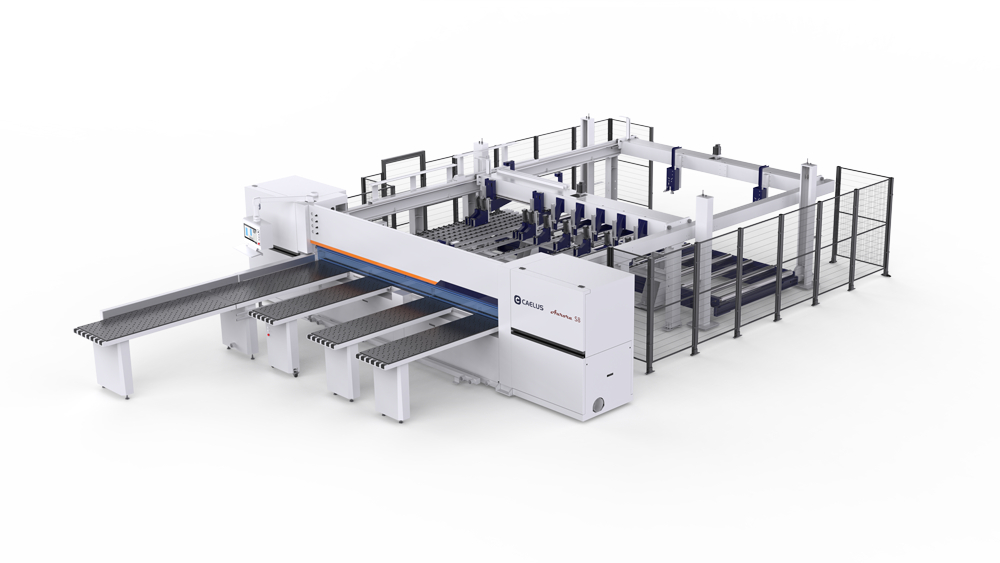

The Caelus Panel Saw series is a high-performance panel processing equipment designed specifically for furniture manufacturing. It integrates heavy-duty structure, high-precision servo drive, and intelligent control system, providing stable, efficient, and flexible panel machine solutions for factories worldwide. Whether cutting conventional panels or processing composite materials such as acrylic and nylon, Caelus' beam cutting saw, Auto Panel Saw, and CNC machines deliver a smooth, butter-slicing experience.

Core Common Values and Technical Features of the Caelus Panel Saw

Regardless of the specific model, the Caelus Panel Saw series shares the following common advantages:

1. Highly Precise Cutting Performance

Utilizing a high-rigidity structure and a high-precision servo/linear drive system, the cutting position accuracy reaches industrial-grade standards.

The combination of a main saw and a scribing saw achieves smoother edges and eliminates chipping.

Cutting accuracy is the first step in ensuring the aesthetics of subsequent edge banding, drilling, and installation.

2. Intelligent Control System

Standard or optional intelligent software (such as optimized scheduling software) supports automatic cutting path planning and improved panel utilization.

A user-friendly interface is easy to use and can interface with industrial software such as MES and warehousing systems.

Automatic positioning and programmed control reduce human error.

3. High-Efficiency and Stable Processing Capabilities

The main saw supports high-speed cutting and automatic lifting, and is driven by a high-power servo or permanent magnet motor.

The secondary saw (marking saw) can achieve dual-feed pre-processing to improve cut quality.

High-speed feeding and return speed design significantly improves production cycle time.

4. Excellent Material Adaptability

Capable of cutting various wood-based panels, composite panels, decorative panels, and other commonly used materials in furniture manufacturing.

Optional expansion functions such as plastic cutting modules and laser detection can be added according to process requirements.

5. Automation and Flexible Production Support

The series supports integration with automatic feeding, automatic labeling, automatic unloading, and intelligent storage systems (such as StoreTek 5) to achieve a smart factory-level automated production system.

High-end models (such as SawTekRob 5) can achieve automatic board rotation, automatic flipping, and multi-process integrated cutting.