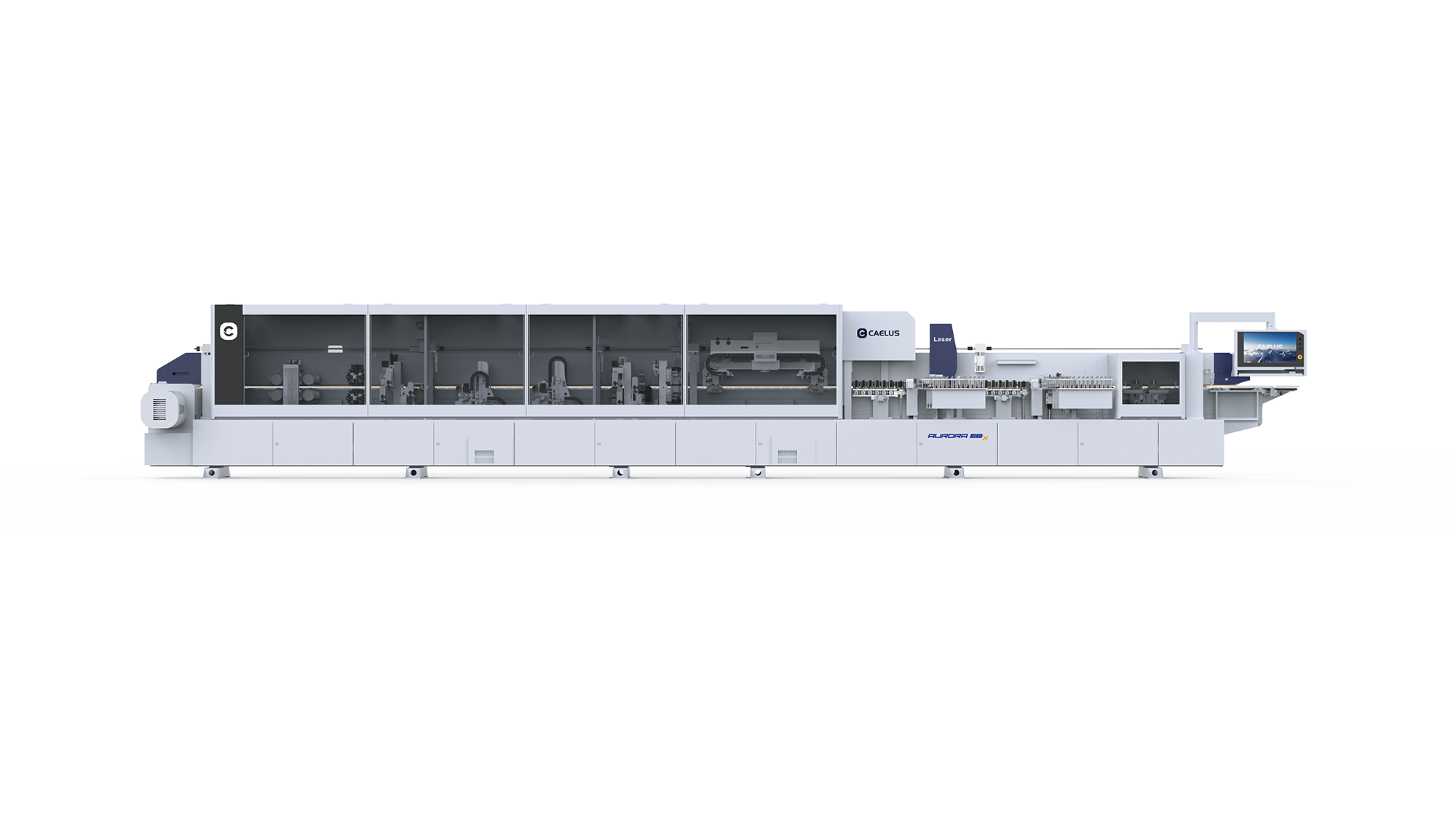

In modern furniture manufacturing and panel processing systems, edge banding is one of the key processes that ensures the quality of furniture edges and overall appearance. Caelus's Edge Bander Aurora series is designed for efficient automation and high-precision edge banding processes, representing a leading model of edge banding machines.

The Edge Bander Aurora not only efficiently performs standard edge banding operations but also integrates intelligent control, process flexibility, and high-speed operation capabilities, making edge banding more precise, stable, and scalable. Whether for large-scale mass production or multi-style furniture customization, the Aurora series provides exceptional performance for furniture manufacturers and is an ideal choice for promoting intelligent manufacturing and automation upgrades.

Core Advantages of the Aurora Series Edge Bander:

1. High-Precision Edge Banding Quality

The Edge Bander Aurora utilizes an advanced control system and high-precision transmission, achieving stable and consistent edge banding quality for straight edges, curved edges, and complex corners.

High-precision edge banding is a crucial aspect of improving the appearance and durability of furniture products, directly impacting subsequent installation and product experience.

2. Intelligent Automatic Control

Built-in intelligent control software supports parameter presets, automatic operation, and process adjustments, making operation simpler and more intuitive. Aurora also features automatic error correction and adaptive processing capabilities, significantly reducing manual setup time.

3. Efficient and Stable Processing Capability

The Aurora series supports high-speed continuous operation while ensuring uniform adhesive application and tight edge bonding during the edge banding process. Combined with a precision feeding and clamping system, it makes panel processing more efficient.

4. Multi-functional Edge Banding Process Support

Supports a variety of edge banding materials and process options, compatible with different furniture panels and design requirements; providing richer appearance styles and process performance for products.

5. Seamless Integration with Automation Systems

The Edge Bander Aurora can be integrated with panel saws, automated storage systems, and other automation modules to build a complete intelligent production line, providing crucial support for furniture factories to achieve an automated workflow "from cutting to edge banding to the next process."

Typical Application Scenarios

- High-precision edge banding for furniture manufacturing companies

- Custom furniture and small-batch diversified production

- Automated production lines integrated with intelligent panel cutting and automatic warehousing

- Improving product appearance quality and production efficiency

The Caelus as a Edge Bander Manufacturer is an important component in achieving intelligent, standardized, and mass production of high-value furniture manufacturing.