The Caelus Panel Saw Pilot series is a core panel machine product line designed for modern furniture manufacturing and automated furniture manufacturing scenarios. This series of panel saws combines high-precision cutting, stable structure, and automation capabilities, and is widely used in panel processing and high-volume furniture production lines, making it an ideal choice for industrial-grade and CNC panel saws.

As a professional panel saw machine manufacturer, Caelus deeply integrates heavy-duty mechanical structures, intelligent control systems, and automation interfaces, making the Panel Saw Pilot series suitable not only for standalone use but also for seamless integration with Automatic Panel Storage, building a complete automated panel processing system.

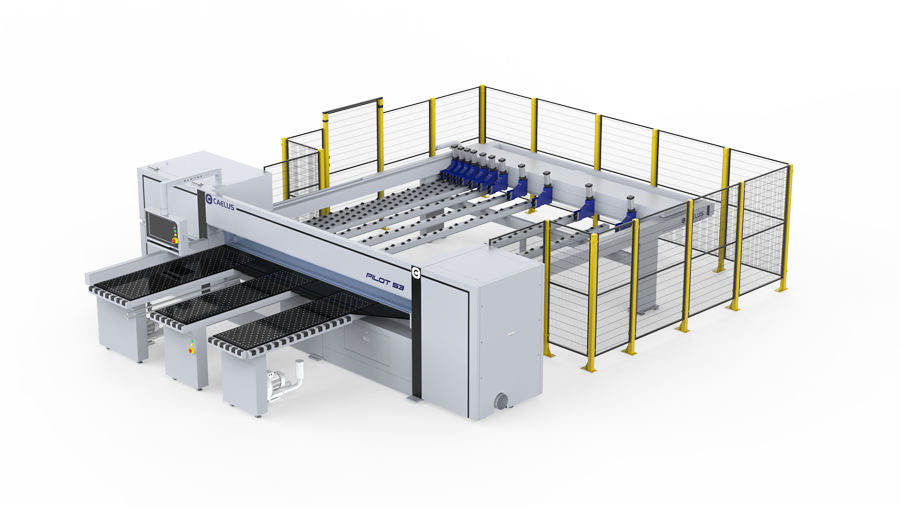

Panel Saw Pilot S3

The Pilot S3 is positioned as an "industry benchmark" panel saw pilot, providing practical and reliable basic automation capabilities while ensuring cutting accuracy. It is an ideal starting point for small and medium-sized furniture manufacturing enterprises moving towards automation.

A panel saw that balances stability and cost-effectiveness, suitable for conventional panel processing scenarios.

Equipped with an intelligent sawing control system, heavy-duty high-rigidity frame, and high-density clamps to ensure stable and repeatable cutting accuracy.

Meets the requirements of high-precision panel processing for linearity and dimensional consistency.

Supports optional solutions such as plastic cutting modules and adaptive pressure beams to expand the range of processing materials and processes.

Suitable for small and medium-sized furniture factories, custom furniture factories, and start-up automated furniture manufacturing projects.

The Pilot S3 is an automatic panel saw that combines reliability and expandability, and can be used as a standalone cutting machine or as a basic node for subsequent automation upgrades.

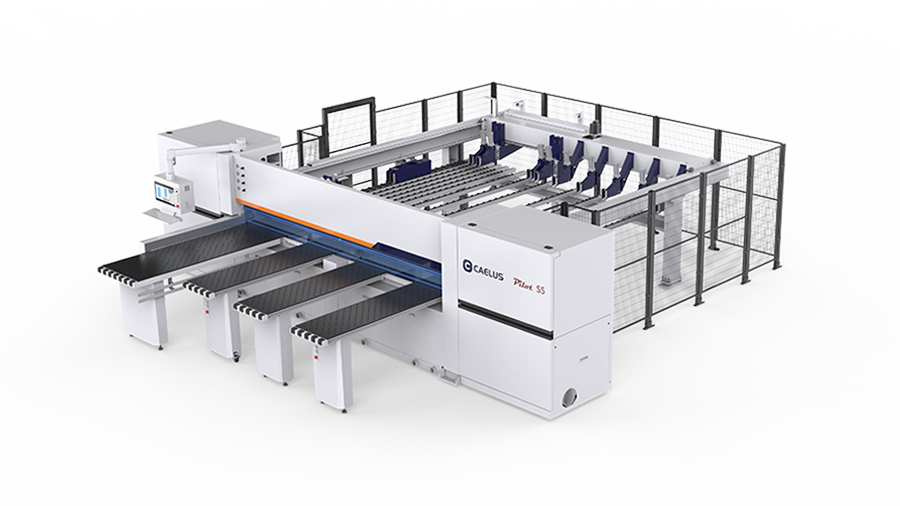

Panel Saw Pilot S5

The Pilot S5 is designed for high-capacity and high-precision requirements, and is a true industrial panel saw and high-performance CNC panel saw, suitable for fast-paced, continuous production furniture manufacturing environments.

The main saw lifting uses servo control, and the saw frame is driven by a linear servo system, achieving a stable combination of high speed and high precision.

Equipped with an independent dual-push system and intelligent flexible work clamps, significantly improving cutting efficiency and panel utilization.

Designed specifically for high-load panel processing and continuous production conditions.

Supports online operation with Automatic Panel Storage, upstream logistics systems, and other panel machines.

It is a core cutting unit for building high-end automated furniture manufacturing production lines.

The Pilot S5 is not just a cutting machine, but a key hub for achieving efficiency, precision, and automation synergy in high-end panel processing production lines.

The Value of Panel Saw Pilot in Automated Furniture Manufacturing

By integrating the Panel Saw Pilot series with Caelus's Automatic Panel Storage, edge banding, and CNC machining machines, furniture manufacturers can achieve:

- Automated flow of panels from storage and retrieval to cutting

- More stable high-precision panel processing quality

- Higher machine utilization and lower reliance on manual labor

- Future-proof automation and smart factory upgrade capabilities

This makes the Panel Saw Pilot series not just a panel saw, but a key component in Caelus's automated panel processing system.